Very cool !

Results 11 to 20 of 27

Thread: New to the forum

-

02-03-2015, 09:35 PM #11Member

- Join Date

- Sep 2013

- Location

- Paso Robles Calif.

- Posts

- 155

-

02-26-2015, 09:31 AM #12

-

02-26-2015, 09:31 AM #13

not much movement during the week. I spend most nights at the GF's house....

I was home to run some errands, pay some bills etc. Got one of the heads assembled. These springs have a lot of pressure. They literally turned my (autozone style) claw compressor thing into a pretzel had to order the tool seen in the picture

-

02-26-2015, 09:32 AM #14

-

02-26-2015, 09:33 AM #15

-

02-26-2015, 09:34 AM #16

-

02-26-2015, 09:34 AM #17

Well left work early to get some work done on the boat, and of course never works out like you think it will

I came home, soda blasted the intake manifold, And I have to say. The 15 pound soda blaster from Hartbor freight kicks some ass. But it does make a mess, but who cares it's baking soda!

Here's what the intake looked like after about 5 minutes of blasting (aircraft stripper failed)

And I said it makes a mess...

But all in all it worked pretty damn nicely.

-

02-26-2015, 09:35 AM #18

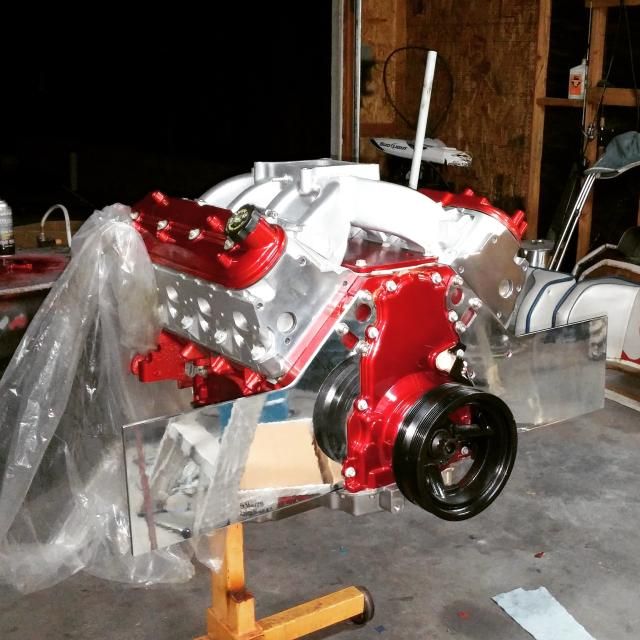

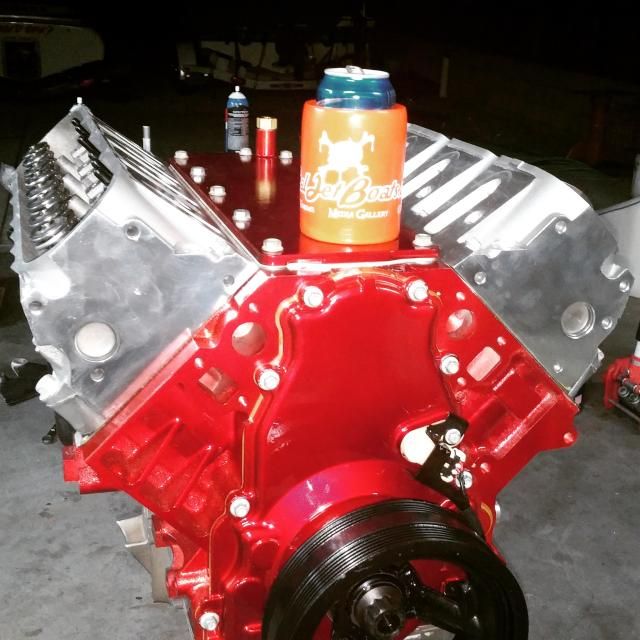

After the soda fiasco. I turned to checking out the front motor plates I bought on eBay.

God I hope they work...

So I polished one real quickly just to see if I wanted them polished, painted, or raw aluminum

After I did that I decided to start making my rear plate.

I used a transmission bellhousing for a template and went to town. Its hard to tell but I got the circle about halfway cut out, went to start on the other side and the damn Chuck for my jig saw died. It will not hold a blade anymore :-(

So it was back to polishing

I did 0 prep on these plates. Just took them to the buffer with various grit rouges and different wheels. Here's one plate about half way through

And the final result

I painted the intake with vht cast aluminum paint.

-

02-26-2015, 09:36 AM #19

-

02-26-2015, 09:37 AM #20

So this weekend ended up busy with the family, but I still managed to get a little bit of work done on the boat.

Started out Friday night with the polishing above.

Saturday I woke up and went to harbor freight and grabbed a jig saw.

The same damn thing happens and the saw wouldn't hold the blade. So after tightening it down, I broke the collet

So back to harbor freight.... Again.

I decided to buy an "old school" saw. One where you have to bolt the blade in.

And I finished the cut, finally

Then I started on the rest of the plate.

About halfway through my third jig saw decided to catch on fire

(Hard to see in this pic)

After this I quit with the jig saws and used my scroll saw. About 5 blades later I had my rear plate. Woohoo!!

Reply With Quote

Reply With Quote

Bookmarks