Cool picture.

Theres that mag driven fuel pump like on Panic Mouse. Damn that had to out some torsional strain on the camshaft!!

Shooter, did you twist of the pump drive on Hocho? Can you imagine driving the mag and the fuel pump?

Morse dry stack, naturally And a Morbet hydraulic throttle. Morse cables must not have been as smooth as they are today.

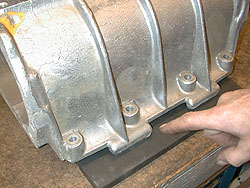

Strangest thing is, the blower still has the lip on this side to help "hang" the blower on the side of a diesel engine while to the bolts are installed. Usually that lip is machined away to match the other side. If you notice the ribs on the blower look very "deep" and taper out the very edge of the blower. When the blower case is machined off, those ribs are flat about the last 1" or so and the blower hold down bolts are closer to the edge of the case.

On the later 6-71, there were 2 tabs, on the early blowers it was one continuous lip.

Never seen a blower setup for racing with the lip still on the original GMC case. On some engines like Pontiacs, Olds, and SBC, the lip will hit the valve covers, so they usually all get machined off.

But my favorite is the chrome plated Home Depot water plumbing fittings. AN was simply tooooo expensive to use for water. But chroming brass fittings was cheap.

Results 651 to 660 of 1008

-

12-26-2013, 05:24 PM #651

Last edited by gn7; 12-26-2013 at 05:32 PM.

-

12-26-2013, 05:33 PM #652

-

12-26-2013, 05:50 PM #653

All I can really say is you're amazing Bob.

Yes, I broke my pump drive and when I pulled the extension shaft out it was corkscrewed. I would guess the corkscrew twist happened over time but all that force probably would've been too much for a mag.

I don't know anything about those old blowers except that they were used on old school buses (among other things). I have seen the old brass water fittings many times and always thought they were kind of "mickey mouse."

-

12-26-2013, 06:09 PM #654

The deacon trained me to pic thru the pictures. I never really looked all that close until he started looking at the smallest details on the Mouse project. I can see where you have to. They did some strange things back then.

Chrome plated brass plumping hardware was the buck$ up stuff. Plain jane brass or even galvanized was not unheard of on a "budget" deal. I can remember my uncles putting their flatties together with brass stuff, maybe polished to get rid on "brand" and casting look. Then have them pull a few off and have them chromed during the winter months. It was all about the "budget" then.

AN fitting were big bank. Bill's dad use to go to aircraft surplus places and buy surplus lines and cut the ends off, but then still had to buy the hose end and the adaptors. All he could use was the line itself. Big money. Even Rudy's Allison used black hydraulic line and crimped ends for most of the water stuff. And that was top drawer stuff. Stainless braid was almost unheard of.

Of course, we can never forget the cherry red clear fuel lines. This stuff was the shiznit back in the day. Mooneyes still sells this stuff.

-

12-26-2013, 10:20 PM #655

-

12-26-2013, 11:04 PM #656

So why did some of the earliest drag boats run off the snout. They had to know it wasn't as strong and the flywheel flange, and they didn't need it for turning on a circle course anymore than a drag boat does today. So what was the reason????

-

12-26-2013, 11:27 PM #657

-

12-26-2013, 11:41 PM #658

-

12-27-2013, 12:20 AM #659

I imagine that it's something simple and logical like a casting or an ignition or maybe it has to do with Reynolds #'s. I just don't know!

I'm tired of racking my brain Bob and I now have a headache from over use so would you just answer you own question so I can get some sleep! please.

-

12-27-2013, 09:07 AM #660

Maybe it just seemed strange to them mounting an engine backwards

Last edited by westair; 12-27-2013 at 09:18 AM.

Reply With Quote

Reply With Quote

Bookmarks